Polyester Film For FRP Panel/Pipes/Tanks

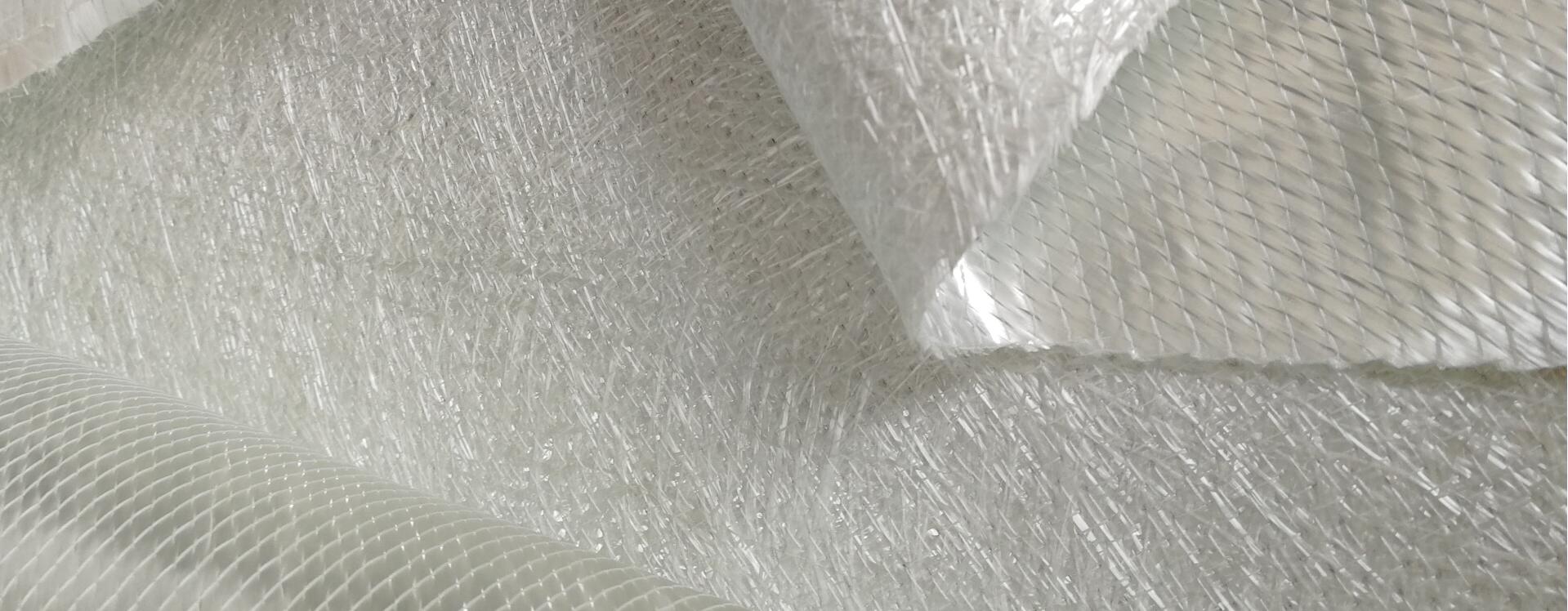

Polyester film/ Mylar, is made of polyethylene glycol terephthalate(PET), one kind of film which manufactured via biaxially oriented(BOPET). It can be used in various fields: FRP panel, FRP pipe & tank, packages,…

Application One: FRP Panel

Brief Introduction

According to the different requirements of the customers, the polyester film can be divided into

film with corona treatment and film without corona treatment. The polyester film with corona

treatment is mainly for some special usage and the film will be kept on the FRP panel to protect

the panel or strengthen the property of the panel (UV resistant etc.).The normal thickness used

for FRP panel are 19um, 23um, 36um etc. and the width can be decided by the customers. The

roll length of the polyester film is adjustable.

Technical Specification (19um)

|

Properties for control reports |

Accepted Standard | |

| Standard No. | Standard Value | |

| Thickness Tolerance (%) | ASTM- D374 | 19+/-10% |

| Tensile Strength md (mpa) |

ASTM-D882 |

≥150 |

| Tensile Strength td(mpa) | ≥150 | |

| Elongation md (%) | ≥60 | |

| Elongation td (%) | ≥60 | |

| Heat Shrinkage md(150 C、30min) | ASTM-D1204 | ≤3.0 |

| Heat Shrinkage td(150C,30M IN) | ≤3.0 | |

| Haze (%) | ASTM-D1003 | ≤8.0 |

| Gloss | ASTM-D2457 | ≥100 |

| Melting Point(C) | ≥256 | |

Package

Packed with pallets, 4 rolls per pallet. We can make the diameter of the inner core to be 3 inch or 6 inch according to the requirement of the customers.

Application Two: FRP Pipe& tank

Polyester film used in FRP pipe manufacturing is biaxially oriented film without corona treatment. The main function of the polyester film is for the demoulding of the FRP pipe& tank. The normal thickness used for FRP panel are 19um, 23um, 25um, 36um etc. and the width are mainly 50mm,100mm,150mm and 200mm for du-helical filament winding process and the width are mainly 45mm,50mm for continuous filament winding process. The roll length of the polyester film is adjustable.

Technical Specification (23um)

| Properties for control reports | Standard No. | Average Value | |

| Appearance | White, side whipstitch good, no broken woven, untained. | ||

| Thickness

um |

ASTM D374 | 23~23.10 | |

| Tensile Strength (MPa) | ASTM D882 | MD | 209 |

| ASTM D882 | TD | 267 | |

| Modulus

(MPa) |

ASTM D882 | MD | 4543 |

| ASTM D882 | TD | 4923 | |

| Heat Shrinkage

(%) |

ASTM D 1204 150C/30 m in | MD | 1.2 |

| TD | 0 | ||

| Haze (%) | ASTM D1003 | 2.49 | |

| Gloss (45 Degree) | ASTM D2457 | 129.800 | |

| C.O.F(IN/OUT)

(µs/µk) |

ASTM D1894E | 0.50/0.42 | |

| Density(kg/m3) | 1397.00 | 1397.00 | |

| Wetting Tension

(mN/m) |

ASTM D2578 | 40.00 | |

Package

Packed with pallets. We can make the diameter of the inner core to be 3 inch or 6 inch according to the requirement of the customers. Normally the diameter of the inner core we make is 6 inch.

Post time: Feb-23-2023